Cov Neeg Muag Khoom Sab Saum Toj Suav Teb Ci Hom Kev Kub Ceev 6 Xim BOPP Zaj Duab Xis Flexographic Flexo Printing Tshuab Nqe

Cov Neeg Muag Khoom Sab Saum Toj Suav Teb Ci Hom Kev Kub Ceev 6 Xim BOPP Zaj Duab Xis Flexographic Flexo Printing Tshuab Nqe

Peb sim ua kom tau zoo tshaj plaws, pabcuam cov neeg siv khoom ", vam tias yuav yog cov neeg ua haujlwm koom tes zoo tshaj plaws thiab lub tuam txhab dominator rau cov neeg ua haujlwm, cov neeg muag khoom thiab cov neeg yuav khoom, paub txog tus nqi sib koom thiab kev lag luam tas mus li rau Cov Neeg Muag Khoom Sab Saum Toj Tuam Tshoj Ci Hom Kev Kub Ceev 6 Xim BOPP Zaj Duab Xis Flexographic Flexo Printing Tshuab Nqe, Ua raws li lub tswv yim lag luam me ntawm 'cov neeg siv khoom 1st, mus tom ntej', peb zoo siab tos txais cov neeg siv khoom los ntawm koj lub tsev thiab txawv teb chaws los koom tes nrog peb.

Peb sim ua kom tau zoo tshaj plaws, pabcuam cov neeg siv khoom ", vam tias yuav yog cov neeg ua haujlwm koom tes zoo tshaj plaws thiab lub tuam txhab dominator rau cov neeg ua haujlwm, cov neeg muag khoom thiab cov neeg yuav khoom, paub txog tus nqi sib koom thiab kev lag luam txuas ntxiv mus rauTuam Tshoj Ci Flexo Xovxwm, Ci Tshuab Luam Ntawv, Peb tau nrhiav lub sijhawm los ntsib txhua tus phooj ywg los ntawm ob qho tib si hauv tsev thiab txawv teb chaws rau kev koom tes yeej-yeej. Peb vam tias yuav muaj kev koom tes ntev nrog nej txhua tus ntawm lub hauv paus ntawm kev sib pab thiab kev loj hlob sib xws.

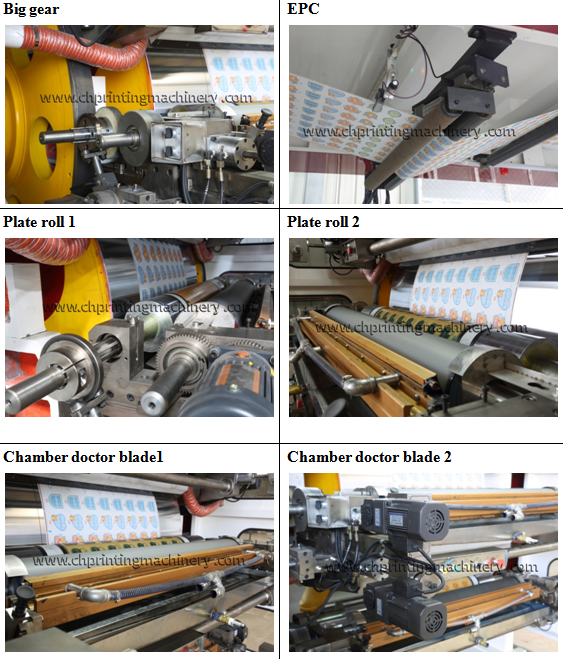

Yam ntxwv

- Lub tshuab qhia & kev nqus ntawm European technology / txheej txheem tsim khoom, txhawb nqa / ua haujlwm tag nrho.

- Tom qab mounting lub phaj thiab sau npe, tsis tas yuav sau npe, txhim kho cov qoob loo.

- Hloov 1 pawg ntawm Plate Roller (tso cov menyuam qub tawm, ntsia rau rau tus menyuam tshiab tom qab nruj), tsuas yog 20 feeb sau npe tuaj yeem ua tiav los ntawm kev luam ntawv.

- Lub tshuab thawj lub phaj mount, ua ntej-ntxiab muaj nuj nqi, kom ua tiav ua ntej prepress ntxiab hauv lub sijhawm luv tshaj plaws.

- Lub tshuab ua haujlwm siab tshaj plaws ceev txog li 200m / min, kev sau npe raug ± 0.10 hli.

- Qhov tseeb ntawm kev sib tshooj tsis hloov pauv thaum lub sijhawm tsa kev khiav ceev nce lossis nqis.

- Thaum lub tshuab nres, Kev nruj tuaj yeem tswj tau, lub substrate tsis hloov pauv.

- Tag nrho cov kab ntau lawm los ntawm lub reel kom muab cov khoom tiav lawm kom ua tiav cov khoom tsis tu ncua, ua kom cov khoom tsim tau zoo tshaj plaws.

- Nrog rau qhov ua kom raug, kev ua haujlwm yooj yim, kev saib xyuas yooj yim, qib siab ntawm kev ua haujlwm tsis siv neeg thiab lwm yam, tsuas yog ib tus neeg tuaj yeem ua haujlwm.

cov lus qhia txog kev siv tshuab

| Qauv | CHCI-E (Kho kom haum rau kev tsim khoom thiab kev ua lag luam) | ||

| Qhov Dav Dav Tshaj Plaws ntawm Lub Vev Xaib | 650 hli | 850 hli | 1050 hli |

| Qhov Dav Tshaj Plaws ntawm Kev Luam Ntawv | 550 hli | 750 hli | 950 hli |

| Qhov Ceev Tshaj Plaws ntawm Tshuab | 300m/feeb | ||

| Kev Ceev Luam Ntawv | 250m/feeb | ||

| Max. Unwind/Rewind Dia. | φ800mm | ||

| Hom Tsav Tsheb | Tsav iav | ||

| Phaj tuab | Phaj photopolymer 1.7mm lossis 1.14mm (lossis yuav tsum tau teev tseg) | ||

| Kua mem | Cov kua mem dej los yog cov kua mem kuab tshuaj | ||

| Qhov ntev ntawm kev luam ntawv (rov ua dua) | 400mm-900mm | ||

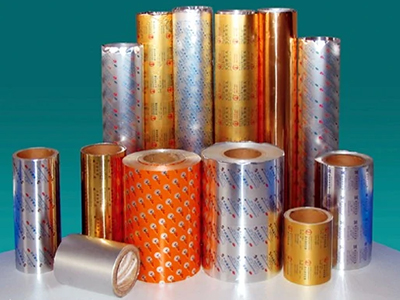

| Ntau Yam Khoom Siv | Zaj duab xis, NTAWV, TSIS MUAJ, ALUMINUM FOIL | ||

| Kev muab hluav taws xob | Voltage 380V. 50 HZ.3PH los yog yuav tsum tau teev tseg | ||

Chav unwinder

- Ib qho chaw tsav tsheb hauv nruab nrab, nrog servo motor, Inverter tswj Closed-loop.

- Kev tswj qhov nruj: Txais yuav lub teeb ntab roller. kev them nyiaj tsis siv neeg, kev tswj lub voj voog ze.

- Cua ncej thauj khoom.

- EPC (kev tswj qhov chaw ntug): Teeb tsa thiab khiav plaub hom yob tsis siv neeg EPC ultrasonic detector system; Nrog manually/txiav txim siab/nruab nrab rov qab ua haujlwm, tuaj yeem kho sab laug thiab sab xis nyob ib puag ncig ± 65 hli dav.

Chav Luam Ntawv

- Tus naj npawb ntawm cov ntawv luam tawm: 4/6/8

- Hom tsav: Iav tsav

- Tsav tsheb: Servo Tsav tsheb; Inverter tswj kev tswj lub voj voog kaw

- Txoj kev luam ntawv: 1) Phaj - Photopolymer phaj; 2) Ink-water base los yog solvent ink

- Luam Rov Ua Dua: 400-900mm

- Gearing ntawm lub tog raj kheej luam ntawv: 5 hli

Kws kho mob hniav

- Chamber hniav 4/6/8 pcs

- Ob txoj kev hniav aluminium alloy number case box.

- Lub thawv number case kaw (lub sijhawm siv thawj zaug 30-60 hnub).

- Hniav qhib thiab kaw los ntawm tes (Kev Nyab Xeeb).

- Nruab nrog chav kho mob rau kev hloov pauv sai.

- Nws yog ua los ntawm Aluminium alloy thiab kaw hom kom txo cov kuab tshuaj volatilization thiab khaws cov kua mem hauv viscosity zoo thiab huv.

- Muaj tus kws kho mob mus tom ntej thiab rov qab mus rau hauv lub chamber. Tus kws kho mob rov qab yog rau kev kaw lub chamber thiab tus kws kho mob mus tom ntej yog rau kev khawb cov kua mem.

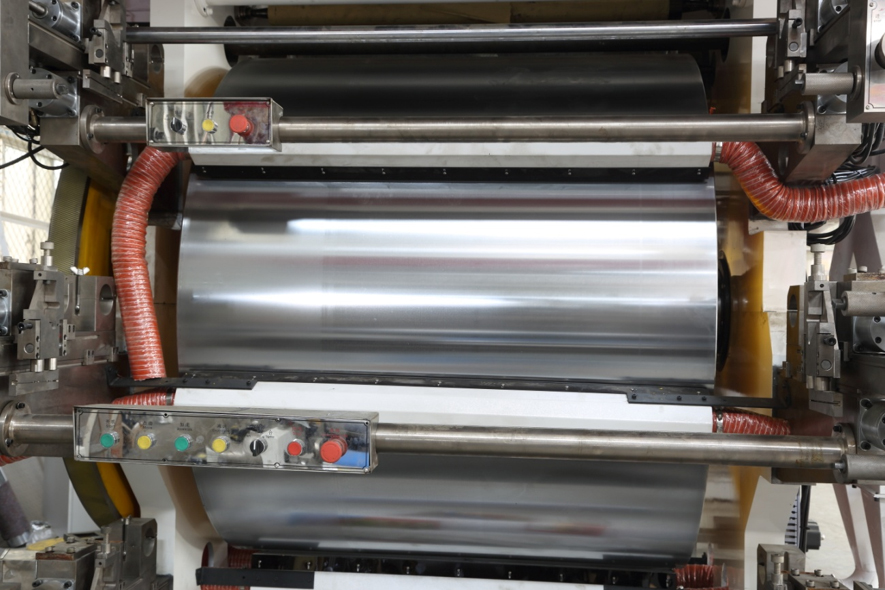

Lub Nruas Loj Nruab Nrab

- Nto ntawm lub hauv paus nias rau cov menyuam nrog qhov kub tas li.

- ±0.008 hli

- Kev tswj qhov tseeb: tsis pub dhau ± 1 ℃

- Txoj kab uas hla: Ф 1200mm / 1600mm

- Ua nyob rau hauv Suav teb

- Lub nruas nruab nrab txais yuav hollow nrog ob txheej qauv, ua los ntawm cov hlau alloy zoo dua thiab kev kho kom zoo dynamic balance thiab kev kho electroplated nto kom ua rau lub thav duab nto tsis muaj etching.

- Lub nruas nruab nrab txais yuav cov menyuam ob kab uas muaj qhov tseeb siab.

Tshuab ziab khaub ncaws ntawm txhua xim

- Kev siv hluav taws xob los ua cua sov, hloov mus ua cua sov los ntawm kev sib pauv cua sov. Kev tswj qhov kub thiab txias siv kev tswj qhov kub thiab txias ntse, kev sib txuas tsis tas kov, teeb tsa 2 kev tswj, haum rau ntau yam thev naus laus zis, ib puag ncig tsim khoom, txuag hluav taws xob, siv PID kev tswj qhov kub thiab txias thiab kev tswj qhov kub thiab txias kom raug, ± 2 ℃.

- Lub thawv qhuav ntawm txhua xim muaj windleitung thiab rov qab cua yeeb nkab.

- Lub hau stainless hlau, aluminium alloy tsuag nozzle.

Lub tshuab ziab khaub ncaws

- Hom cua kub: Siv hluav taws xob los ua cua sov, hloov mus ua cua sov los ntawm kev sib pauv cua sov. Kev tswj qhov kub thiab txias siv kev tswj qhov kub thiab txias ntse, kev sib txuas tsis tas kov, teeb tsa 2 kev tswj, haum rau ntau yam thev naus laus zis, ib puag ncig tsim khoom, txuag hluav taws xob, siv PID kev tswj qhov kub thiab txias thiab kev tswj qhov kub thiab txias kom raug, ± 2 ℃.

Cov qauv ntawm lub qhov cub kom qhuav

- Lub thawv sab hauv ntawm lub qhov cub ziab.

- Lub tshuab hloov cua sov.

- Muzzle yog txhua yam ua los ntawm cov hlau tsis xeb.

- Qhov cub qhuav muaj lub kiv cua ywj pheej rau cua nkag thiab lub kiv cua ywj pheej rau cua tawm. Los ntawm kev tswj qhov nrawm ntawm cua nkag thiab kho qhov cua damper, cov txheej txheem luam ntawv ntawm lub tshuab yuav tau txais qhov cua ceev zoo tshaj plaws, cua siab, qhov cub qhuav ua kom sov zoo dua, thiab txuag hluav taws xob; Lub tog raj kheej tswj qhov qhib thiab kaw ntawm qhov cub qhuav, nrog rau qhov chaw tiv thaiv thiab pem teb taug kev.

Rov qab ib zaug xwb

- Ib chav siv lub hauv paus tsav rewind, servo motor, Inverter kaw-voj tswj.

- Kev tswj qhov nruj: txais yuav lub log super lub teeb ntab, thiab kev them nyiaj tsis siv neeg, kev tswj lub voj voog kaw.

- Tshuab nres tsis siv neeg thaum rhuav cov khoom; Thaum tshuab nres, khaws qhov nruj thiab zam cov khoom xoob lossis kab deflection.

- Cua ncej loading

- Lub teeb tshuaj xyuas

Lub kaw lus saib xyuas duab zoo li qub

- Kev daws teeb meem zaub: 1280 * 1024

- Qhov ua kom loj dua: 3-30 (Qhov ua kom loj dua ntawm thaj chaw)

- Hom zaub: Puv npo

- Lub sijhawm thaij duab: txiav txim siab los ntawm PG encoder / iav sensor qhov chaw teeb liab.

- Lub koob yees duab kuaj xyuas ceev: 1.0m/min

- Tshawb xyuas ntau yam: nyob ntawm qhov dav ntawm cov khoom siv, teeb tsa raws li qhov xav tau. Nws zoo rau kev saib xyuas qhov chaw kho tau lossis rov qab los tsis siv neeg.

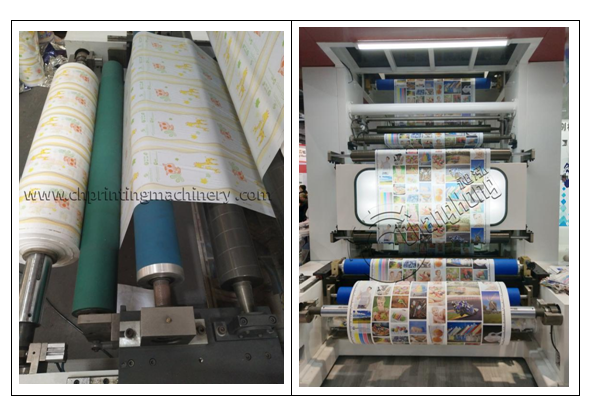

Cov Qauv Luam Ntawv

Cov ntaub ntawv ua tiav tseem ceeb

Daim ntawv

Zaj duab xis

Tsis yog ntaub

Ntawv Nyiaj Aluminium

Peb sim ua kom tau zoo tshaj plaws, pabcuam cov neeg siv khoom ", vam tias yuav yog cov neeg ua haujlwm koom tes zoo tshaj plaws thiab lub tuam txhab dominator rau cov neeg ua haujlwm, cov neeg muag khoom thiab cov neeg yuav khoom, paub txog tus nqi sib koom thiab kev lag luam tas mus li rau Cov Neeg Muag Khoom Sab Saum Toj Tuam Tshoj Ci Hom Kev Kub Ceev 6 Xim BOPP Zaj Duab Xis Flexographic Flexo Printing Tshuab Nqe, Ua raws li lub tswv yim lag luam me ntawm 'cov neeg siv khoom 1st, mus tom ntej', peb zoo siab tos txais cov neeg siv khoom los ntawm koj lub tsev thiab txawv teb chaws los koom tes nrog peb.

Cov Neeg Muag Khoom Zoo Tshaj PlawsTuam Tshoj Ci Flexo Xovxwm, Ci Tshuab Luam Ntawv, Peb tau nrhiav lub sijhawm los ntsib txhua tus phooj ywg los ntawm ob qho tib si hauv tsev thiab txawv teb chaws rau kev koom tes yeej-yeej. Peb vam tias yuav muaj kev koom tes ntev nrog nej txhua tus ntawm lub hauv paus ntawm kev sib pab thiab kev loj hlob sib xws.