Hauv kev lag luam ntim thiab luam ntawv, pawg flexo tshuab luam ntawv tau dhau los ua cov cuab yeej tseem ceeb rau ntau lub lag luam vim lawv qhov yooj yim thiab ua haujlwm tau zoo. Lawv muaj peev xwm ua hauj lwm nrog cov substrates sib txawv thiab hloov mus rau ntau yam ntawm cov khoom ntim tau ua rau lawv muaj kev xaiv mus rau ntau lub Hoobkas tab tom nrhiav kom muaj kev sib tw. Tab sis nyob rau hauv kev ua lag luam uas lub sij hawm xa tuaj kom txo qis thiab cov qauv zoo tsuas yog nce mus, kev yuav cov tshuab siab dhau lawm tsis txaus. Lub siab tiag tiag tam sim no zaum ntawm kev txhim kho cov khoom tsim tau - zam qhov tsis tsim nyog downtime, ua kom cov ntawv luam tawm zoo ib yam, thiab nyem cov zis ntau li ntau tau los ntawm txhua qhov kev hloov pauv ntau lawm.Tsis muaj qhov no tuaj yeem ua tiav los ntawm kev cia siab rau ib qho kev hloov pauv; nws hu rau kev sib koom tes ntawm kev npaj ua haujlwm, kev tswj cov khoom siv thiab kev muaj peev xwm ntawm tus neeg ua haujlwm.

Cov khoom siv tu: lub caj qaum ntawm cov khoom ruaj khov

Rau stack-type flexo printers, stability thiab precision ua los yog rhuav koj cov khoom tsim tau. Ua raws li kev saib xyuas tsis tu ncua yog dab tsi ua kom lawv khiav lag luam ntseeg tau thiab ua tau zoo mus sij hawm ntev.Case hauv point: xyuas cov iav, bearings, thiab lwm yam tseem ceeb rau hnav. Hloov cov khoom qub, hnav cov khoom raws sij hawm, thiab koj yuav zam tsis tau qhov kev npaj txhij txog uas kaw lawm. Tsis tas li ntawd, tweaking luam ntawv siab, nro, thiab sau npe txoj hauv kev yuav txo cov khib nyiab thiab ua rau koj cov zis zoo dua. Siv cov ntawv luam ntawv zoo thiab anilox rollers pab ib yam nkaus-lawv txhawb kev hloov pauv tus lej zoo npaum li cas, yog li koj tau txais kev nrawm dua thiab tau txais txiaj ntsig zoo dua.

Txheej txheem optimization: lub cav tsav tsheb tiag tiag efficiency nce

Hauv flexographic ntau lawm, kev ua haujlwm tsis tshua muaj kev txiav txim siab los ntawm ib qho. Ib pawg hom flexo tshuab luam ntawv suav nrog lub network ntawm kev sib cuam tshuam sib txawv - number case viscosity, luam ntawv siab, tswj nruj, kev ua kom qhuav, thiab lwm yam. Kev tsis sib haum me ntsis hauv ib qho ntawm cov chaw no tuaj yeem ua rau tag nrho cov kab ntau lawm. . Txhim kho cov txheej txheem teeb tsa thiab txo qis lub sijhawm hloov pauv tuaj yeem xa cov txiaj ntsig tam sim.Piv txwv li, siv cov cuab yeej siv hluav taws xob preset-qhov chaw luam ntawv rau cov khoom sib txawv tau muab khaws cia rau hauv lub kaw lus thiab rov qab nrog ib nias thaum lub sijhawm hloov pauv - txo lub sijhawm npaj.

Tus neeg ua haujlwm kev paub ncaj qha cuam tshuam rau kev tsim khoom.

Txawm tias lub tshuab luam ntawv zoo tshaj plaws flexo tsis tuaj yeem ncav cuag nws lub peev xwm tsis muaj cov neeg ua haujlwm txawj ua haujlwm. Kev cob qhia tsis tu ncua pab cov neeg ua haujlwm paub txog lub tshuab muaj peev xwm, yuav ua li cas kho cov teeb meem sib txawv, thiab hloov txoj haujlwm sai npaum li cas - qhov no txo qis ntawm tib neeg kev ua yuam kev thiab qeeb los ntawm kev ua haujlwm tsis raug.Cov neeg ua haujlwm uas paub txog lawv txoj hauv kev nyob ib puag ncig cov cuab yeej tuaj yeem khaws cov kev hloov me me thaum khiav: me ntsis hloov hauv qhov nro, yuav ua li cas tus number case nteg, lossis thaum ntxov qhia tias muaj ib yam dab tsi tawm. Lawv yuav dhia nrawm ua ntej qhov teeb meem me me yuav raug kaw.Tsim cov kev txhawb nqa los txhawb cov neeg ua haujlwm los hloov cov txheej txheem thiab tuaj nrog lawv tus kheej kev txhim kho tsim kom muaj kab lis kev cai ntawm ib txwm ua tau zoo dua - thiab qhov no yog qhov tseem ceeb rau kev ua kom muaj txiaj ntsig zoo nyob rau lub sijhawm ntev.

● Video Taw Qhia

Kev txawj ntse txawj hloov dua tshiab sawv cev rau yav tom ntej sib

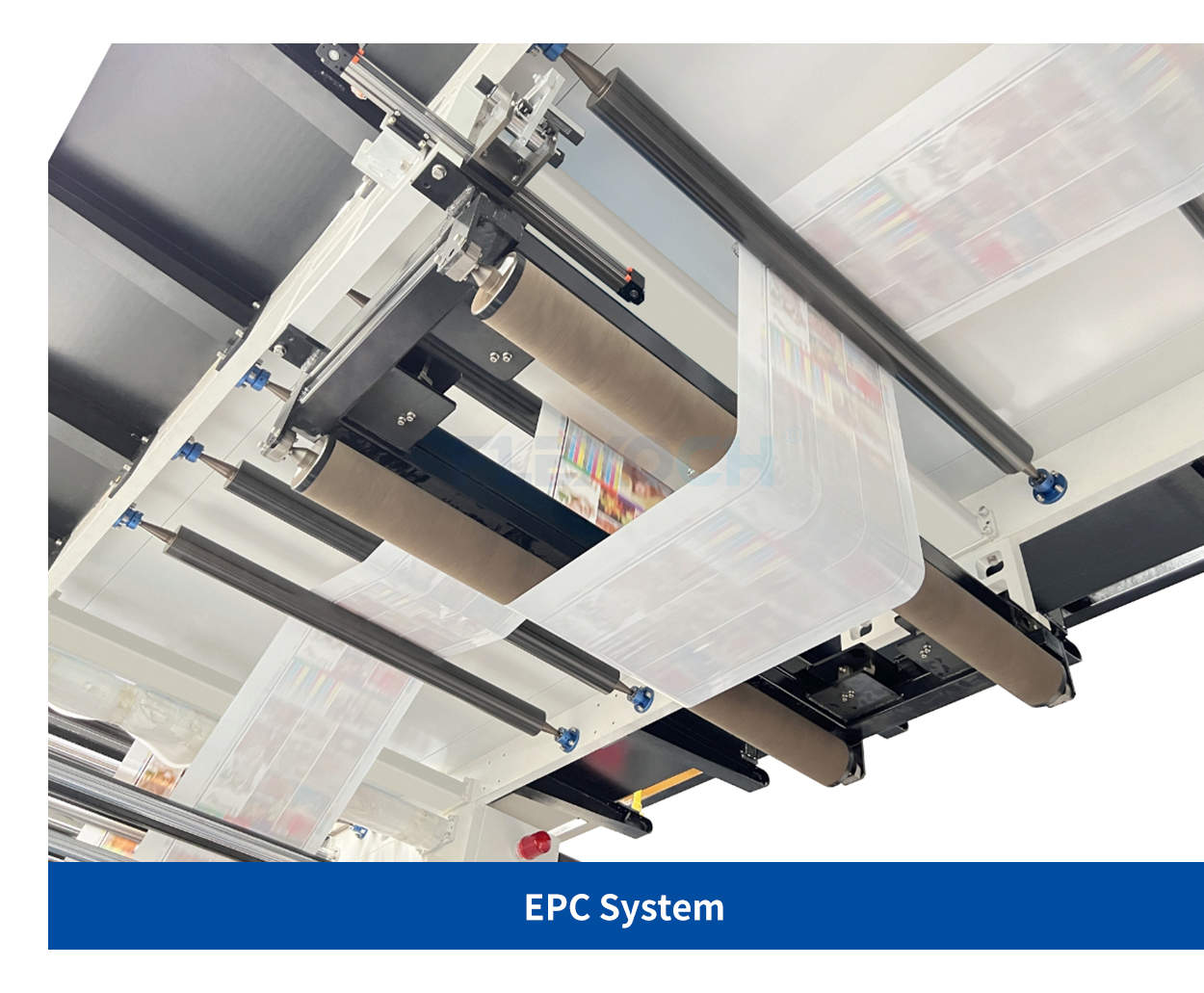

Raws li kev lag luam hloov mus rau Kev Lag Luam 4.0, kev txawj ntse automation tau dhau los ua tus sib tw sib tw tom ntej. Kev sib koom ua ke xws li kev tswj hwm kev sau npe tsis siv neeg, kev kuaj pom tsis zoo hauv kab, thiab cov ntaub ntawv-tsav cov txheej txheem dashboards rau hauv flexo pawg xovxwm ua rau txo qis kev cuam tshuam ntawm phau ntawv thaum txhim kho kev luam ntawv thiab kev ruaj ntseg ntau lawm. Inline soj ntsuam systems niaj hnub no muaj ntau ntse dua li lawv tau ua. Lawv phim txhua qhov luam tawm tawm tsam cov duab siv hauv lub sijhawm tiag tiag thiab hu tawm cov teeb meem ua ntej lawv tig mus rau hauv ib pawg ntawm cov khoom siv khib nyiab. Kev hloov kho tshiab zoo li qhov no yuav zoo li me me, tab sis lawv hloov pauv qhov kev sib tw ntawm kev tsim khoom txhua hnub-kab khiav tsis tu ncua, cov teeb meem tau daws sai dua, thiab kev ua tau zoo tuav tau yam tsis muaj kev tua hluav taws tas li.

Kev tshawb fawb ntau lawm: ib qho tseem ceeb tsis tau feem ntau overlooked kom zoo dua

Amid lub laub rau cov cuab yeej ntse dua thiab tswj cov txheej txheem nruj dua, kev teem sijhawm ntau lawm tau txais kev saib xyuas tsawg dua li qhov nws tsim nyog. Hauv kev muaj tiag, thaum cov khoom lag luam loj hlob tuaj thiab lub sijhawm xa khoom poob qis, kev sib koom ua haujlwm tsis zoo tuaj yeem ua rau cov khoom lag luam ntsiag to - txawm tias nyob hauv cov chaw nruab nrog cov tshuab ua haujlwm siab heev. Kev npaj tswv yim raws li kev txiav txim ceev, kev ua haujlwm nyuaj, thiab lub sijhawm tiag tiag ntawm txhua qhov flexo pawg xovxwm tso cai rau cov tuam txhab txo qis kev cuam tshuam kev hloov pauv thiab khaws cov khoom ruaj khov.

Qhov tseem ceeb sib npaug yog muaj kev txawj ntse thiab kev qhuab qhia rau kev tswj cov khoom. Koj yuav xav khaws cov khoom lag luam ruaj khov, cov khoom siv hluav taws xob, cov ntawv luam tawm, thiab cov khoom tiav ib nrab ntawm tes - txoj kev no, kev tsim khoom yuav tsis sib tsoo kom nres vim qee yam khiav tawm ntawm lub sijhawm phem tshaj plaws.Yog cov ntaub ntawv tshwm sim thaum koj xav tau - tsis muaj kev khaws cia thaum ntxov, tsis muaj sijhawm kawg - koj qhov kev ua haujlwm nyob twj ywm. Cov xovxwm yuav dov es tsis txhob zaum idle tos cov khoom siv, thiab lub sijhawm poob qis heev.Ntau lub sijhawm, koj tuaj yeem txhawb nqa tag nrho cov khoom tsim tawm yam tsis tau yuav khoom tshiab. Nws tsuas yog hais txog kev npaj zoo dua thiab kev sib koom ua ke ze zog ntawm kev yuav khoom, chaw muag khoom, thiab kev tsim khoom.

Post lub sij hawm: Lub Xya hli ntuj-10-2025